| Hitch | Comments |

|---|---|

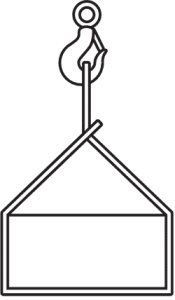

Vertical Hitch | One end is placed on the hook, while the other end is attached directly to the load. A tagline should be used to prevent load rotation. |

Choker Hitch | Sling passes through one end around the load and the other end is placed on the hook. Rated capacity is normally 80% of that for a vertical hitch. Load control is a potential problem with only one sling rigged in a choker hitch. Also, the choke point should always be on the sling body—not on the fittings, base of the fitting or tag. |

Basket Hitch | The sling cradles the load while both ends are attached overhead. The rated capacity for a basket hitch is twice that for a vertical hitch. As with the choker hitch, more than one sling rigged in a basket hitch (or some other means) may be necessary to help ensure load control. |

| Angle “A” in degrees from horizontal | Tension Multiplier |

|---|---|

| 90 | 1.000 |

| 85 | 1.004 |

| 80 | 1.015 |

| 75 | 1.035 |

| 70 | 1.064 |

| 65 | 1.104 |

| 60 | 1.155 |

| 55 | 1.221 |

| 50 | 1.305 |

| 45 | 1.414 |

| 40 | 1.555 |

| 35 | 1.742 |

| 30 | 2.000 |

| Multiply the load weight (per leg) by the tension factor to determine the increased tension of the sling leg(s) |

| Angle of Choke (degrees) | Angle of Choke Reduction Factor |

|

|---|---|---|

| = or > | < | |

| 120 | 180 | 1.000 |

| 105 | 120 | 0.82 |

| 90 | 105 | 0.71 |

| 60 | 90 | 0.58 |

| 0 | 60 | 0.50 |